Air compressors are devices that must be subjected to systematic maintenance and regular services. This action ensures their long life, expected performance and minimizes the risk of sudden failures. Properly selected spare parts and consumables allow you to keep compressors in excellent condition, ensuring long and uninterrupted operation. What elements and materials need to be replaced in compressors? We encourage you to read the article.

What needs to be replaced in an air compressor?

Systematic service and maintenance of the compressor guarantees its long and uninterrupted operation. An air compressor, like any mechanical device, requires replacement of wearing parts and consumables as the number of operating hours increases. It is worth emphasizing that compressor service and maintenance allow you to determine which system elements require replacement with new ones. Moreover, each compressor has designated replacement intervals for specific parts and materials specified in service plan. Performing the recommended activities allows you to keep the machine in good condition for the next period of operation.

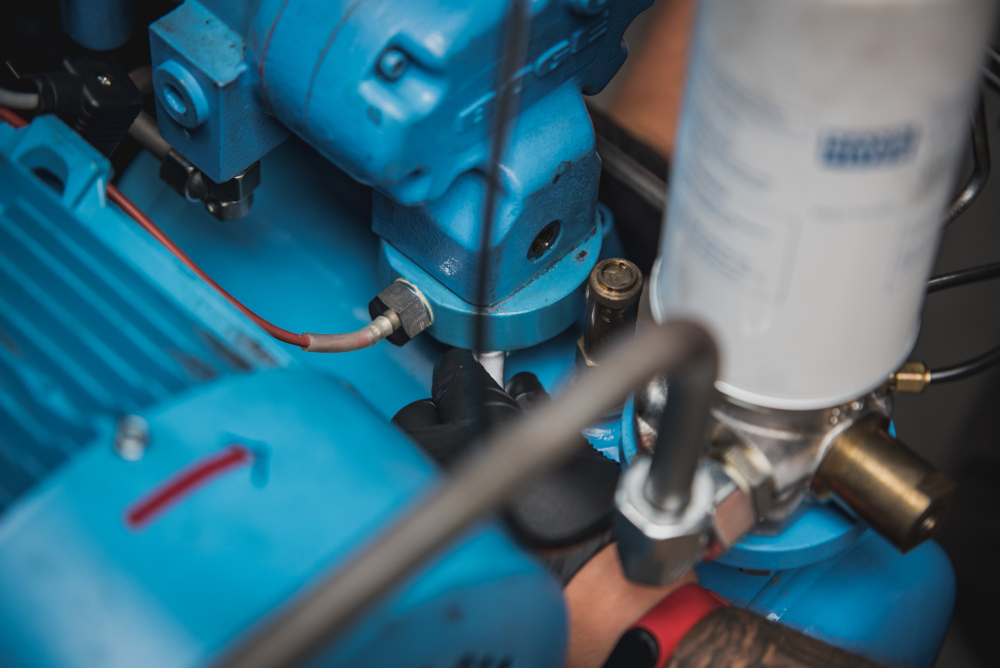

The most frequently replaced parts and consumables include: compressor oil, V-belts and pulleys. They are also subject to periodic replacement oil filters, air filters, filter mats, as well as bearings, seals, oil gauges, valves, drain plugs, oil fillers and drain plugs with magnets catching metal contaminants.

It is worth emphasizing that each compressor has its own service recommendationsy observe. Spare parts and consumables must be precisely matched to the compressor model, its power, the parameters of the gas produced, as well as to the method and mode of operation. For this reason, there is a wide range on the market spare parts and consumables for compressors. They can serve as an example compressor oils. You should always choose those with appropriate chemical and physical properties. There are plenty to choose from mineral and synthetic compressor oils. Why is it so important? Oil in compressors serves to protect against overheating, ensures proper sealing, removes deposits and protects against thermal degradation and oxidation. In addition, more advanced products have anti-foaming and anti-corrosion properties.

Systematic is also important replacing oil filters and air filtersand also infilter layers and filter mats. Their task is to eliminate contaminants that could get into the compressed air system.

Substitutes or original spare parts – which to choose?

From the wide range of spare parts and consumables available on the market, you can choose between originals and cheaper substitutes. However, it is worth remembering that substitutes are usually of lower quality, durability and do not guarantee a long period of operation. As a result, they may contribute to more frequent failures, the effects of which may be much more severe for the compressor. Moreover, the lower quality of non-original parts and consumables will translate into a shorter service life and, therefore, the need for more frequent replacement. This entails not only the costs of double and sometimes even more frequent purchases, but also the costs of service. Short-sighted saving can lead to higher expenses in the future, including damage and the need to replace the compressor. In the case of non-original consumables, the risk is even higher - low quality products will contribute to inadequate protection of the device.