Tank-mounted piston compressors are devices commonly used in production and service plants. Their simple design, reliability and low operating costs find supporters in many industries. How do tank-mounted piston compressors work, what are their advantages and where are these devices used?

Piston compressor - principle of operation

A piston compressor is a device that is used to compress air or other gases using a movable piston in a cylinder. Piston compressors work on the following principle:

- when the piston in a reciprocating compressor lowers, it creates a vacuum, drawing air into the compressor through the air inlet,

- the air then passes through the inlet valves into the cylinder. When the inlet valves are open, the outlet valves remain closed. In other words, the air remains in the cylinder,

- when the cylinder is full of air, the piston rises, compressing the air. The consequence of compression is an increase in gas pressure and temperature,

- when a certain pressure is reached, the exhaust valves open and the compressed air is discharged to the tank or to its destination.

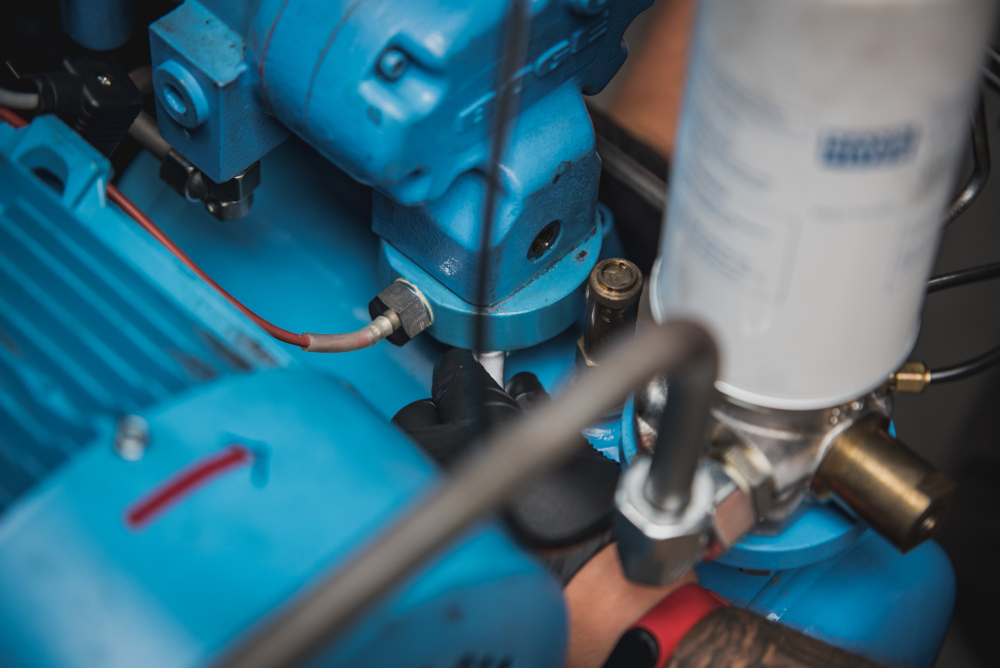

A popular solution are piston compressors mounted on a tank. These devices are usually mounted on a horizontal pressure tank, which serves as a compressed air reservoir.

Piston compressors have many applications in various industries, such as construction, painting, car workshops, compression of technical gases, and home and renovation works.

What types of piston compressors are there?

Piston compressors are devices that are used to compress air or other gases using a movable piston in a cylinder. There are many types of piston compressors available on the market. Different types can be distinguished depending on several criteria.

The first is the number of pistons. Piston compressors may have one, two or three cylinders. The number of pistons affects the compressor's efficiency - the more there are, the higher the compressor's efficiency.

The second criterion is the number of compression stages. Piston compressors can be single-stage or two-stage, which means they compress air once or twice. Two-stage compressors provide greater efficiency and lower energy loss because they compress air in two stages, at lower and higher pressure. Moreover, they allow you to obtain compressed air with higher pressure.

Another criterion is compressor lubrication. There are oil and oil-free compressors available on the market. This means they either use oil or not to lubricate the moving parts of the piston and seals. Oil compressors have better lubrication and cooling, but they pollute the compressed air with oil and require filters and separators. Oil-free compressors are more ecological and energy-efficient, but require more frequent replacement of components and are less durable.

Piston compressors can also be stationary or portable. Larger devices are usually permanently mounted in one place, while smaller ones may be equipped with wheels or mounted on carts, so they can be easily transported. Stationary compressors are larger and more powerful, but less flexible. Portable compressors, on the other hand, are smaller and lighter, but less efficient.

What are the advantages of tank-mounted piston compressors?

Tank-mounted piston compressors have many features that are appreciated by users. These compressors ensure low operating costs. This is due, among other things, to the pressure tank that stores the compressed medium. This way, the compressor turns on less often and therefore consumes less electricity.

The devices are simple and do not require frequent servicing or replacement of parts. Thanks to less frequent switching on, compressors wear out less. At the same time, they always provide the expected amount of compressed medium.

The car is also easy and uncomplicated to operate. Piston compressors are easy to set and adjust operating parameters, as well as easy to clean and maintain. Moreover, their performance remains constant. Piston compressors are able to maintain a constant flow and pressure of compressed air or gas, regardless of external conditions. Moreover, a constant supply of compressed air from the pressure tank reduces pulsation in the network.

The advantage of tank-mounted piston compressors is a wide selection of different solutions. The machines are available in various sizes, powers and tank capacities, which allows you to easily select a solution suitable for a specific plant or application.

It is worth emphasizing that tank-mounted piston compressors are suitable for both individual use and large companies and enterprises. Tank-mounted piston compressors can be used to power pneumatic tools, in cleaning and drying processes, material transport, packaging, aeration, pumping and mixing. Tank-mounted piston compressors can also be used in various industries such as mechanical, vulcanization, food, furniture, wood, pharmaceutical, chemical and medical.