Compressed air that has not been treated is a medium with a high content of impurities. What impurities can be found in the compressed medium? Where do they come from? How to remove contaminants from compressed air? We will tell you all about this in the article below.

What contaminants are in compressed air?

Compressed air is a medium created in the process of compressing atmospheric air sucked in by a compressor. It may contain various types of impurities. It is worth emphasizing that the purity of atmospheric air will have a significant impact on the degree of contamination of the working medium. Typical contaminants in compressed air include moisture, oil particles, solid contaminants and microbiological contaminants.

Moisture is the biggest problem in compressed air. As atmospheric air is compressed, moisture often condenses, causing water to appear in the compressed air system, which may lead to corrosion of all metal elements of the compressed air system (compressors, distribution system and receivers, i.e. pneumatic devices and machines powered by the medium). As a result, water vapor is the factor that has the greatest impact on shortening the life of all parts of the system.

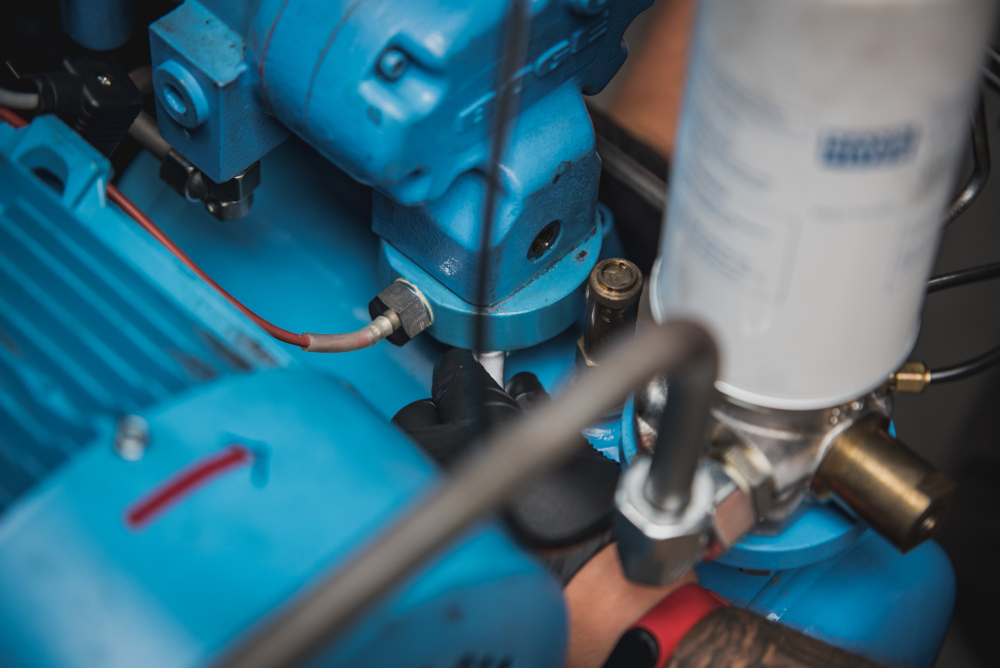

In systems where oil compressors are used to compress air, contamination of the compressed air with oil particles may also be a problem. It may enter the medium and reduce the quality of products manufactured using compressed air and cause damage to pneumatic tools and machines. Oil contamination is unacceptable, among others: in the food, pharmaceutical, medical and electronics industries.

Solid particles are another type of contaminant in compressed air. Their composition depends on the purity of the atmospheric air sucked in by the compressor. These may be dust particles, metal particles, rust, sand and other solid impurities penetrating the compressed air during the compression process.

In the food, pharmaceutical and medical industries, microbiological contamination - i.e. viruses and bacteria - is also important. The sterility of the medium allows you to obtain products with acceptable parameters.

How to remove contaminants from compressed air?

To obtain clean and suitable compressed air for a specific application, it is necessary to use filters and other purification systems to remove these contaminants. This process is important because air cleanliness is crucial in many applications such as industrial, manufacturing, pneumatics, food industry and medicine. Industry standards and norms define compressed air quality requirements depending on the application, which helps maintain compressed air quality at the appropriate level.

How to get rid of moisture from compressed air? In compressed air systems, cyclone separators, refrigeration and adsorption dryers are most often used to dry it. They allow for effective removal of water vapor particles from the medium until it is completely dry. Cyclone separators provide basic compressed air treatment. For more thorough elimination of H2O particles, refrigeration and adsorption dryers are used, which ensure the most thorough drying of the working medium.

Each compressor is also equipped with an air filter system. They are responsible for removing solid particles and dust from the air. Air filters use various technologies such as non-woven filters, active carbon filters and others to retain particulates and other pollutants. Air filters provide various degrees of filtration, which allows you to adjust the compressed air parameters to the requirements of the production process. It is worth emphasizing that filters should be replaced or cleaned regularly to maintain their effectiveness. Carbon filters are used for even more thorough air purification. They ensure effective removal of chemical contaminants and odors from compressed air.

In medical and food applications where cleanliness is key, UV lamps are used to kill bacteria and microorganisms in compressed air. UV sterilization guarantees obtaining a safe compressed medium without microbiological contamination.

An important element of compressed air purification is monitoring its quality. Regular monitoring of air quality and quality control systems allow you to maintain the purity of compressed air at an appropriate level.

It is worth noting that the specific method of removing contaminants depends on the type of contaminants present in the compressed air and the specific application. Therefore, it is important to adapt the purification system to your specific needs and requirements.