Heat recovery in compressed air systems is used to reduce energy consumption, increase energy efficiency and reduce operating costs. This is especially important in the case of large installations where compressed air is widely used in industrial processes.

What is heat recovery in compressed air systems?

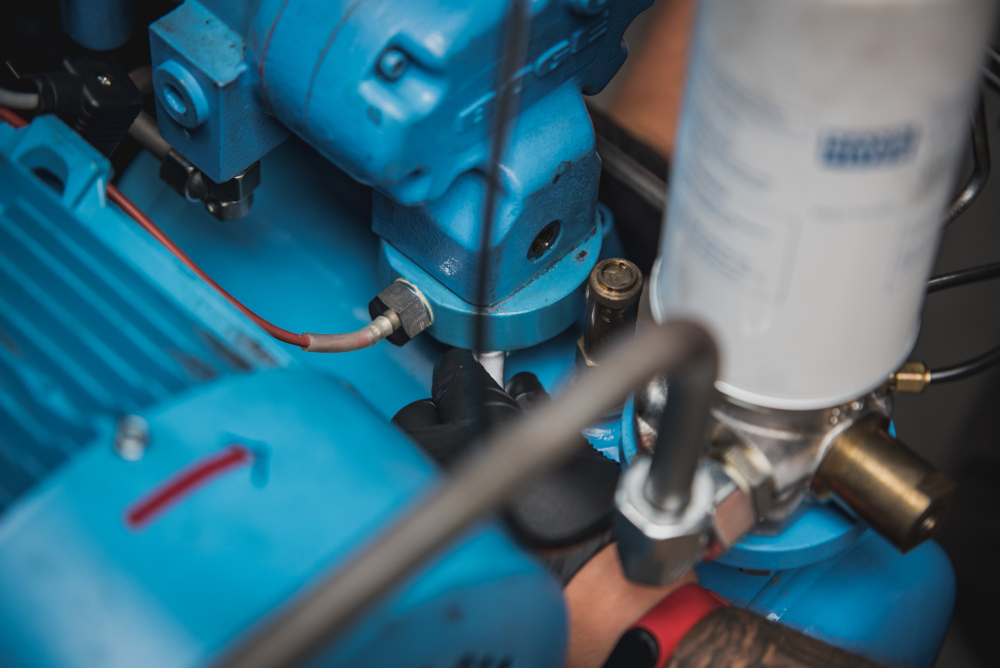

Heat recovery in compressed air systems refers to the process of using the heat generated by compressing air and recovering it to increase the energy efficiency of the system. When air is compressed in compressors, electrical energy is converted into kinetic energy and also into heat. This heat is the result of friction and compression of the air inside the compressor. This is energy that is typically lost and removed from the system by cooling the compressed air before it is used.

However, in systems equipped with heat recovery, the heat generated during air compression is captured and used for other purposes. Depending on the processes carried out in production plants, thermal energy can be used for other tasks.

How can you use the heat generated when air is compressed? There are various ways to recover heat in compressed air systems. The most frequently used method is the recovery of thermal energy through heat exchangers. In this process, the heat generated during air compression can be transferred to another medium, such as water or air, using special heat exchangers. This heat can then be used to heat water, rooms or other heating purposes.

Some compressed air systems use heat regeneration. This is a process in which hot compressed air is passed through special materials, such as adsorbents, that store heat. Then, when needed, the stored heat is released and used, for example, for drying or heating.

Sometimes the hot air generated during compression is used as combustion air. In this process, warm compressed air is used as a source of air for combustion, among others. in boilers, furnaces or burners. This saves the energy needed to heat the air to the required temperature level.

Why is it worth using heat recovery from compressors?wife air?

The air compression process is extremely energy-intensive. The derivative of compression is the production of thermal energy, which is usually released into the environment. In this way, large resources that could be used to improve the operation of the plant are irretrievably lost. Using heat recovery from air compression has many benefits that improve energy consumption parameters in the plant, reduce operating costs and increase the company's prestige as an entity committed to caring for the natural environment.

Heat recovery has a direct impact on increasing the energy efficiency of the plant. This process makes it possible to use energy that would otherwise be lost as waste heat. By recovering and reusing this thermal energy, the energy efficiency of your compressed air system can be significantly increased. As a result, less energy is used, which leads to lower operating costs.

Recovering heat from the compressed air process also translates into savings in energy costs. Using recovered heat saves energy costs because there is no need to reheat or warm the medium (e.g. water or air) with an additional energy source. Using waste heat for heating or process purposes can significantly reduce energy bills.

Another parameter worth taking into account is reducing the negative impact on the natural environment. Heat recovery from compressed air contributes to sustainable development and reduction of greenhouse gas emissions. Instead of wasting heat that would have to be generated by traditional energy sources, the existing heat generated by air compression is used. This leads to a reduction in the use of fossil fuels and greenhouse gas emissions, which helps protect the environment.

Importantly, the recovered heat can be used in many directions in one plant. It can be used for space heating, water heating, heating processes, and as a source of combustion air. This versatility allows for flexible use of recovered thermal energy according to specific needs and requirements.

In summary, using heat recovery from air compression has a positive impact on energy efficiency, cost reduction, environmental protection and sustainability. It is a practice that is used in many industries and systems, bringing numerous benefits, both economic and environmental.