In times of dramatically rising business costs related to electricity prices, every entrepreneur strives to optimize expenses related to the operation of devices. One of the most effective methods for companies using compressed air as a working medium is a network audit. What is a compressed air audit and what benefits does it bring to the company?

Compressed air audit – what nim is?

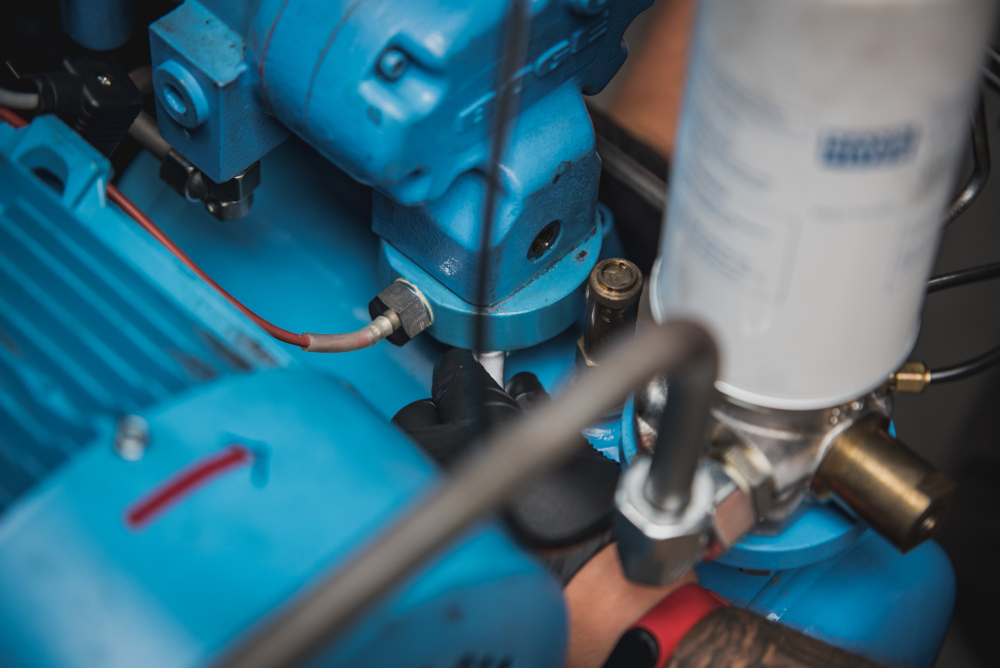

Compressed air network audit consists in checking and assessing the system's performance, as well as the effects related to its functioning. The purpose of the audit is to examine the efficiency of equipment and improve the functioning of the compressed air system by optimizing its operation. To conduct an audit of a compressed air network, it is necessary to measure the pressure and gas flow in order to eliminate possible losses. A properly performed audit should also locate leaks and indicate necessary actions that will help restore full efficiency and effectiveness of the air compression system. The repairs should result not only in higher efficiency of the compressed air system, but also in lower operating costs.

Compressed air system audit – what should it include?

A compressed air network audit consists of several different stages, which result in obtaining reliable results on the basis of which corrective actions can be carried out to optimize the operation of the system. The first step is to examine the operation of the compressor by measuring the load on the equipment. Then the medium flow is measured. This task is performed using a probe installed in the installation. This device allows you to check the efficiency of all system elements. An important element of a compressed air network audit is the measurement of the medium pressure and the dew point. The final stage is the detection of compressed air leaks.

After taking all measurements, our experienced team of technicians interpret them and then inform the client about the inspection results. In this way, the entrepreneur receives complete knowledge about the actual condition of the compressed air installation (including both compressors and devices - e.g. dryers, separators, as well as the condition of the entire transmission network). At the same time, the client receives specific recommendations, which should performed to increase the efficiency of the entire compressed air system.

When should you order an audit of your compressed air network?

If your company has a compressed air system, you can order an audit at any time. Especially when you notice a decrease in system performance or an unjustified increase in the costs of its operation. Companies often decide to conduct audits periodically in order to constantly monitor the system's performance and systematically improve its operation.

When should you order a compressed air audit? This task is worth performing, especially when leaks appear in the installation - i.e. leakage of the medium, which directly affects the decrease in the efficiency of the entire system, including lowering the pressure in the system and increasing the costs of compressed air production. Leaks in the system will lead to a variety of problems that will make working with this medium difficult. The solution is to audit the compressed air network and implement corrective actions.

Performing an audit of the compressed air network may have another purpose - to increase efficiency and optimize the compressed air production process. Optimization aims to increase efficiency and reduce the costs of their work. Thanks to the information obtained during the audit, you can select appropriate compressors for the installation's needs and set their operating parameters in a way that ensures the expected efficiency and minimization of costs. A properly conducted audit and implementation of the recommendations contained therein will allow you to eliminate energy losses while using the full capabilities of the devices used in the system.