Compressed air purification is necessary for proper production, a high level of services provided and a longer life of pneumatic tools. Filters are the basic accessory responsible for removing contaminants from compressed air. Therefore, it is worth carefully considering the decision to choose specific filters for the compressor. We explain what the possibilities are and suggest which of them will work best.

Should you always buy a filter for your air compressor?

It sometimes happens that investors, when purchasing an air compressor, forget that supplying the plant with compressed air does not end at this stage. Compressor filters are not a standard element included in the set. Therefore, it is necessary to purchase filters appropriately selected for the parameters of the air compressor, the requirements for the use of compressed air and the nature of the operation of the entire plant. Additionally, constant control of the quality of compressed air is required. Without these elements, the quality of compressed air can be much lower than expected, causing damage to production. That is why the proper operation of the air compressor is so important, which cannot be done without properly selected air treatment equipment.

The purity of compressed air is crucial both for the final effect of the production process and for the quality of the services provided by the company. In places where compressed air is used to power pneumatic tools, the purity of this medium determines the reliability and operation time of the machines. Lack of proper filtration of compressed air may result in complete plant downtime due to major failures or minor faults. Therefore, under no circumstances should you forget or ignore the need to purchase a filter for your air compressor.

What to consider when choosing a compressor filter?

When choosing a compressor filter, you should take into account several factors that will allow you to more precisely match it to your needs and the type of compressor used. It is worth remembering that the situation is slightly different in areas requiring the highest purity of compressed air. These include the medical, pharmaceutical, chemical and food industries. In such plants, it is necessary to additionally protect the system against any contamination, because the quality of compressed air has a direct impact on the safety of users. However, everywhere else, when choosing a filter for a compressor, you must take into account the size of the connection, i.e. the type and diameter of the thread with which a specific compressor is equipped and the type of drain between automatic and manual. In addition, the scope of filtration and its precision are also very important. Here you need to determine the protection index of the compressed air against contamination. It will be higher, the greater the need for impeccably clean air.

Air Filter and Oil Filter - Is One Enough?

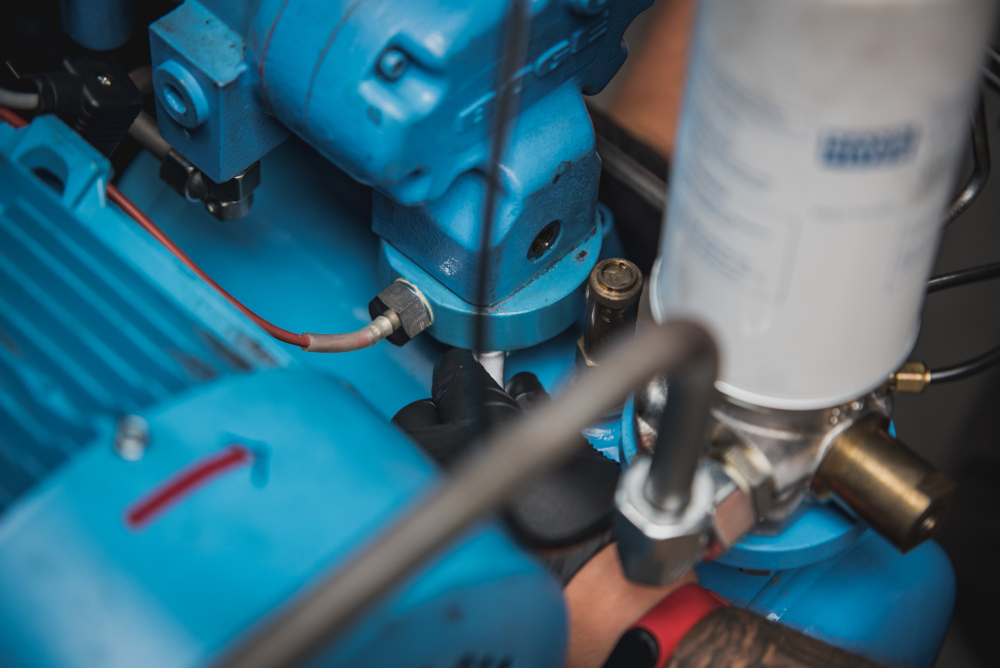

One of the most basic distinctions between compressor filters is the division into air filters and oil filters. It should be remembered that the contaminants found in compressed air that we want to protect ourselves from are not only particles of solid particles, but also oil condensate and water. To make sure that all contaminants have been eliminated from the compressed air, both air filters and oil filters, as well as oil separators, are used. In plants where particularly high quality of compressed air is required, carbon filters are additionally used for compressors, which remove the taste and odor of the compressed gas.

Air filters should not only be carefully and precisely selected, but also regularly replaced. Only this guarantees their reliability and effectiveness. The best and most recommended frequency of replacing the air filter is every 2-2,5 thousand km. device operating hours. The most commonly used compressed air filter is a cartridge filter. It is made of cellulose, cellulose with reinforcement or polyester nonwoven fabric. Oil filters are used to clean compressed air from oil condensate and oil mist. Thanks to their use, the compressor can operate longer and have fewer failures. Oil filters also improve the quality of compressed air.