Every oil compressor produces condensate consisting of a water-oil mixture, which is a side effect of the compression process. Separating these two substances allows for easier and cheaper disposal of condensate, while contributing to environmental protection. What is the principle of operation of a water-oil separator for a compressor and which device should be chosen for specific applications?

Why condensate treatment is important

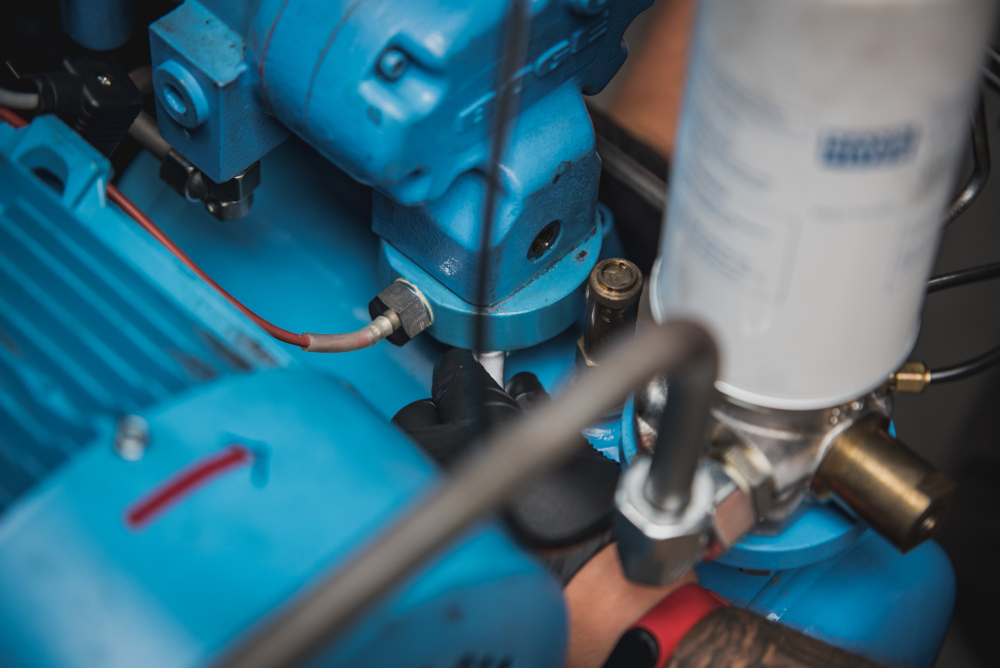

During air compression in oil compressors, both screw and piston compressors, condensate is formed, which is a water-oil mixture taking the form of an emulsion. This substance is a mixture consisting of approximately 99% water and 1% lubricants. Due to contamination with oil particles, the condensate cannot be discharged directly into the sewage system. It should be emphasized that petroleum substances, including oils used in compressors, are highly toxic to the natural environment.

There are two main reasons to use water-oil separators. The first is to obtain condensate with an oil particle content that will be neutral to the environment and will enable the condensate to be disposed of in the sewage system. Polish law prohibits condensate from being discharged into sewage without prior treatment. According to the regulations, only condensate purified from petroleum hydrocarbons to a maximum level of 15 mg/l may be discharged to the network. The second reason is the dramatic reduction in condensate disposal costs resulting from the reduction in the volume of the substance sent for recycling.

Water-oil separator - principle of operation

If a large amount of condensate is produced during the air compression process, it is worth installing a water-oil separator in the pneumatic system. The device allows the separation of water and oil contaminants in a way that allows the treated condensate to be disposed of in the sewage system. This process significantly reduces the volume of concentrated condensate, which contributes to reducing the costs of disposal of the harmful substance. Water-oil separators eliminate oil-derived contaminants using various filters, ensuring that the condensate after treatment contains less than 15 mg/l of oil particles.

ALUP water-oil separators

The choice of water-oil separator should depend on the efficiency of the system, the use of dryers in the installation and the climate in which the compressor will operate. At the same time, it should take into account the type of condensate produced - i.e. whether it is unstable or stable condensate. The latter is more difficult to clean and requires the use of more advanced technology.

It is worth emphasizing that there are already water-oil separators on the market that are perfectly capable of treating both unstable and stable, highly emulsified condensate from piston compressors. Such devices are offered by ALUP, which provides two-stage water-oil separators that use oleophilic and carbon filters or glycosilicate filters to eliminate oil-derived contaminants. OWS separators can be used in all types of compressed air installations using oil piston and screw compressors. Their performance is not related to the type of lubricant used - they work equally well with an emulsion saturated with mineral oil, semi-synthetic oil or polyglycol. In addition, they are excellent at treating unstable and stable condensate in which the natural process of water and oil separation has not yet occurred.

The devices ensure low condensate storage costs (no need to collect condensate in tanks). ALUP water-oil separators are easy to service and use - they use replaceable inserts, which also ensure high water removal efficiency up to 5 ppm. For even simpler operation, ALUP water-oil separators are equipped with a universal system for controlling the residual oil level.