Compressors are the basic element of every compressed air system. The continuity of activities carried out in the plant depends on their proper operation. Moreover, compressed air systems are widely used in the vast majority of industries. Is it necessary to carry out systematic inspections of compressors? Is such a service profitable?

What is a compressor servicing service for?

A compressor inspection allows you to check the correct operation of the device. In this way, minor irregularities in the compressor's operation can be detected and eliminated in advance, thus reducing the risk of major failures to a minimum. During compressor service, specialists monitor the machine's operating parameters. On this basis, they determine the repair of possible faults and can predict upcoming failures.

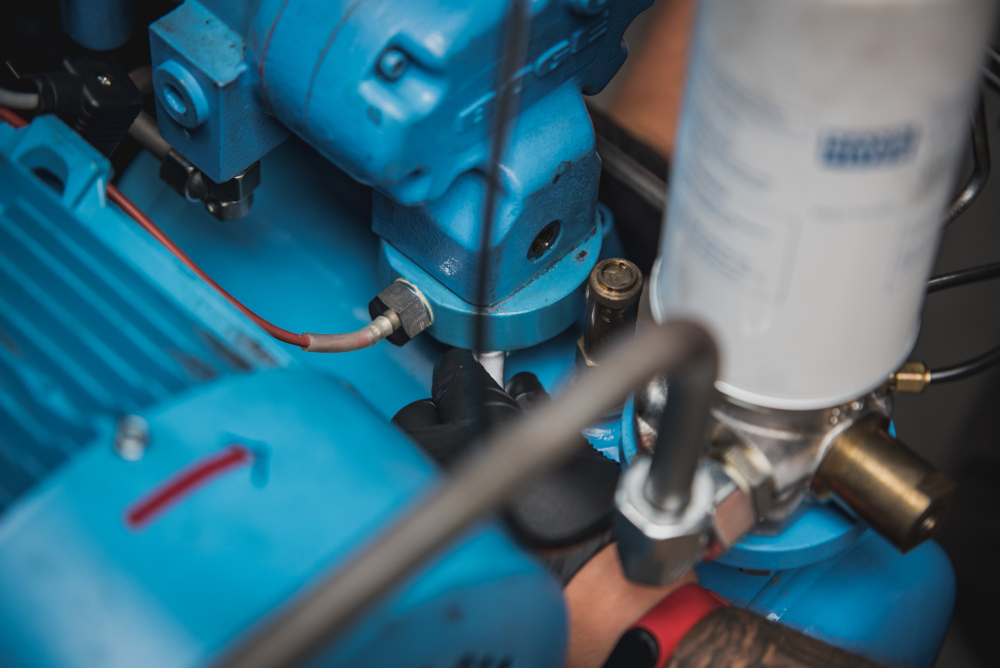

The compressor inspection also includes all activities related to cleaning the device and replacing components and operating fluids. During the work, service technicians should replace the filters, and often also the oil. This action significantly extends the compressor's failure-free operation period and guarantees its full functionality between subsequent services. During the inspection, the service technician will also replace worn out elements.

Why is it worth carrying out systematic inspections of compressors?

Maintaining compressors in good technical condition allows you to significantly reduce the expenditure on equipment repairs. Even though the service is paid, the final balance of expenses is always positive for the customer. There are several reasons.

The first is to avoid the risk of interruptions in access to compressed air and, consequently, in the operation of the plant. In this way, you will minimize the risk of immobilizing compressors and cutting off the production/service line from the working medium. Experienced service technicians will help keep the machines in perfect technical condition ensuring the expected compressor performance. In this way, the plant will be able to conduct production activities without any problems. It is worth emphasizing that the costs of inspection will be many times lower than disabling the line while the equipment is being repaired.

Maintaining compressors in good technical condition also eliminates the risk of damage to tools and devices powered by compressed air. The guarantee of supplying the working medium with the required parameters will ensure efficient operation of powered devices and pneumatic tools at the collection points. In this case, a failure of the compressed air system results not only in the costs of disabling production processes, but also in the costs of repairing the equipment.

Lack of systematic inspections may result not only in the immobilization of the plant. As a result of lack of service, the compressor may suffer a serious failure, which will result in the need to purchase a new compressor. Why? Because the repair costs may exceed the price you will have to pay to buy a new compressor.

The above examples show that the lack of systematic service may result in the plant having to incur significant expenses related to the repair or purchase of new devices. However, it is worth emphasizing that the inspection of compressors also has a positive impact on the daily operation of these devices. Service carried out by a professional company will also result in savings in everyday use of machines. A properly serviced compressor will provide better performance and lower energy consumption. Moreover, a compressor inspection maintains the manufacturer's warranty on the device. Without documented service carried out in accordance with the manufacturer's recommendations, you cannot count on the recognition of claims resulting from damage to the machine during the warranty period.

How often should compressors be serviced? It is appropriate to perform compressor maintenance in accordance with the manufacturer's recommendations. This prevents the loss of warranty benefits. At the same time, such preventive maintenance protects against sudden failures and significantly reduces the risk of stopping production processes in the plant.

In our company, we offer favorable terms of service services, which we adapt to the individual needs of the client. A professional team of service technicians provides customer service throughout Poland. Attractive service contracts and 24/XNUMX access to the service are also advantages of our offer. Contact us and check what else you can expect from our service services.