The variety of types, power and efficiency of compressors available on the market is huge and may pose a problem when making purchasing decisions. At the same time, it gives you the opportunity to choose a device that will fully meet your requirements. So which compressor should you choose for a workshop, paint shop, industrial use, construction or others? Get to know our proposals.

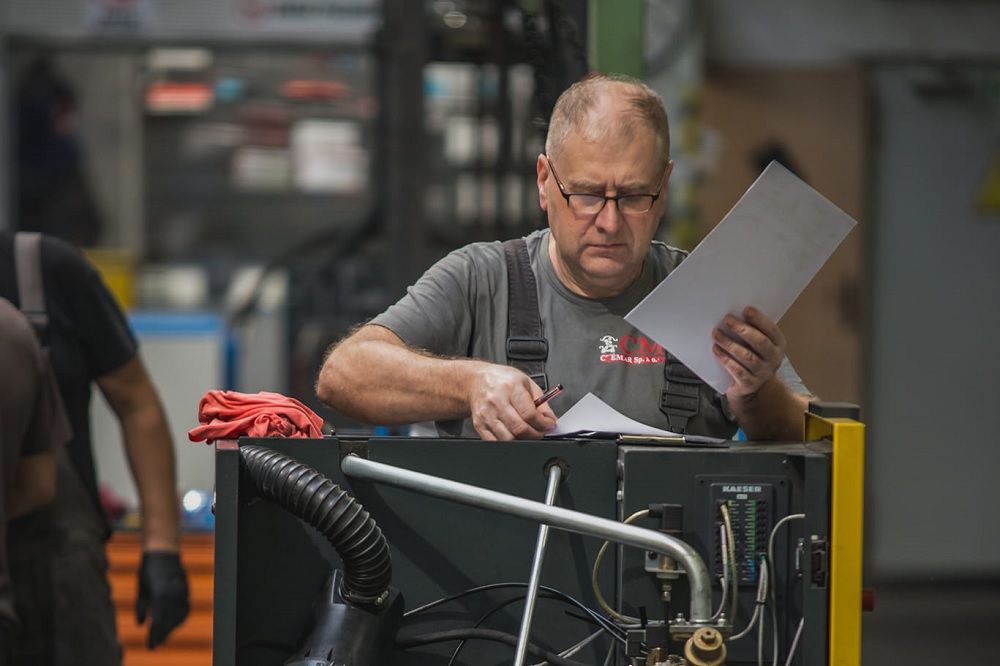

Which compressor for a car workshop?

When purchasing an air compressor for a workshop, you should first check what demand for compressed air the workshop generates, determine the number of pneumatic devices that will be powered by it, the power of the device and the required working pressure. In the case of small plants, we suggest using a piston compressor with parameters adapted to the needs of the collection points. In turn, for larger workshops and those servicing the vulcanization of trucks, we recommend the use of tank-mounted screw air compressors, e.g. Sonetto or MSM.

Paint shop compressor – which one to choose?

In the case of painting workshops, in addition to the quantity of compressed air supplied, its quality also plays an important role. Hence, it is so important to properly clean the compressed gas, thanks to which a smooth, flawless painted surface is obtained. What is important here is both the air filtration used in the compressor and the use of devices that ensure proper cleaning of the gas from oil, water and solid particles. Therefore, in addition to choosing a screw compressor adapted to the demand of consumers and providing the amount of compressed air and enabling constant painting activity, we also recommend the use of refrigerated dryers.

Compressor for workshops where sandblasting is used. How suitable is a compressor for the sandblasting process?

Selecting an air compressor for sandblasting requires determining the required amount of compressed air, the type of proposed variable or constant operating mode, and adapting the compressor to produce compressed gas with appropriate purity parameters. For sandblasting, we recommend devices from a wide range of screw compressors from our offer with appropriate filtration, fixed- or variable-speed, e.g. from the ALLEGRO or RMA series.

When do you need a compressor for construction work?

Compressed air is perfect for construction sites, accelerating work such as plastering, painting, carpentry and roofing work. For this industry, we propose the use of a wide range of piston compressors from our offer. If you do not have access to a generator on site, we recommend using self-propelled compressors.

Do you use blowing of stations or products? Choose the right compressor

If you are looking for an air compressor to blow through stations or products, we recommend using a piston compressor - e.g. an HLE compressor. Our offer includes a large selection of devices with various parameters.

Compressor for an upholstery or carpentry workshop

Our offer includes compressors for large companies in the carpentry and upholstery industries. For such plants, we offer compressors that provide a sufficiently large amount of compressed air adapted to the plant's needs and at the same time guarantee stable demand fulfillment. That is why we recommend screw compressors from the wide range of ALUP or MARK compressors.

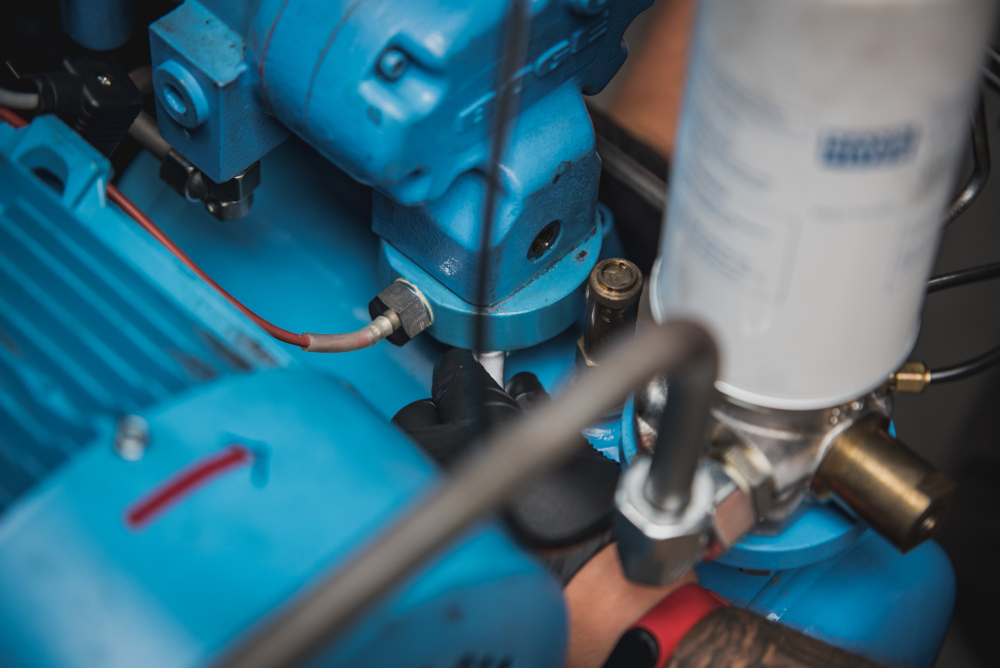

Air compressor for plasma cutting

Plasma cutting requires the use of an air compressor with appropriate capacity. For this purpose, we recommend the use of screw compressors, which should be supported by a nitrogen generator to obtain precise cutting.

Compressor for laboratories – which one to choose?

Depending on the research being conducted, laboratories use either oil-based air compressors with an appropriate filtration system or oil-free compressors in places where the use of compressed air with cleanliness class 0 is crucial - such as oil-free SPR compressors from MARK, OF or WIS. ALUP brand. Additionally, it is worth choosing quiet devices that enable comfortable work.

Compressor for industry – what to pay attention to?

For production processes, you should choose compressors that guarantee constant availability of a medium with specific parameters. This will avoid production downtime. That's why we offer high-efficiency screw compressors with a wide range of performance for industry. LARGO, ALLEGRO or EVOLUTO compressors, which you can find in our offer, will be perfect for the industry.