Pneumatic vacuum cleaners are professional devices that are rarely found in households. This is due to its specificity and purpose, which is aimed at professional applications. But is a pneumatic vacuum cleaner useful in your plant? To determine this, you need to familiarize yourself with the mechanism of operation of this device, its advantages and recommended purpose. We present the most important information about pneumatic vacuum cleaners.

What is a pneumatic vacuum cleaner?

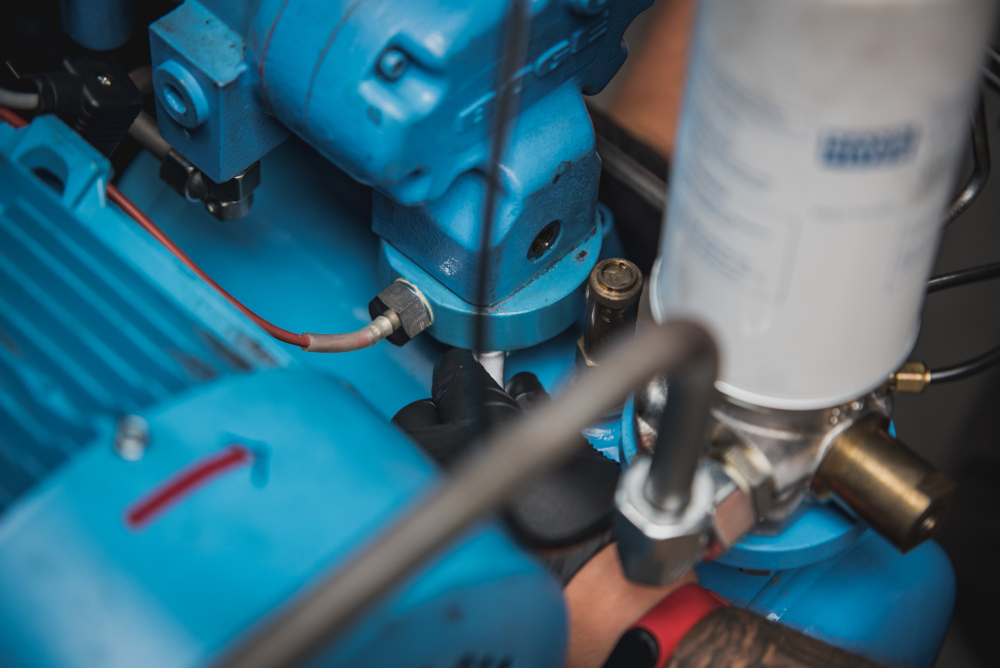

First of all, it should be said that a pneumatic vacuum cleaner bears very little resemblance to a hand-held home vacuum cleaner. A pneumatic vacuum cleaner is essentially a workshop vacuum cleaner with a much higher suction power. For this reason, it is considered an industrial vacuum cleaner used mostly for professional purposes. However, workshop vacuum cleaners and an ordinary home electric vacuum cleaner differ not only in the name. The main feature that distinguishes these two devices is the power source - pneumatic vacuum cleaners do not use electricity. Instead, compressed air is used to clean all surfaces. Therefore, the pneumatic vacuum cleaner must be connected to a compressor or be part of a pneumatic installation that will be a source of compressed air.

Pneumatic vacuum cleaners are the best solution in places without access to electricity or where its use is prohibited for various reasons. These types of industrial vacuum cleaners and construction vacuum cleaners are perfect for collecting solid and dry waste, as well as liquid and wet waste, e.g. sawdust, dry or wet shavings, plastics, and other loose materials. This type of pneumatic accessories is used in car and tire repair workshops and production halls. It is also a very efficient grain vacuum cleaner.

How does a pneumatic vacuum cleaner work?

How does a compressed air vacuum cleaner work? Pneumatic handheld vacuum cleaners powered by compressed air are quite simple in operation. A powerful industrial vacuum cleaner is equipped with a motor that is set in rotation by the pressure of compressed air. This leads to the creation of a vacuum, which in turn allows the extraction of all types of contaminants. The material sucked into the hand vacuum cleaner is accelerated by compressed air and directed to the bottom of the barrel. Steel barrels are the most practical here.

Modern workshop vacuum cleaners are equipped with a filter bag, which eliminates the need for a waste barrel. The air pressure required by pneumatic vacuum cleaners ranges from 5,5 to 6,9 bar. All-in-one pneumatic accessories are becoming more and more common. These are pneumatic vacuum cleaners that perform both vacuuming, blowing and transport functions.

Advantages of pneumatic vacuum cleaners

Such a powerful industrial vacuum cleaner has many advantages. The most important of them is the lack of an engine, which may be exposed to wear or seizure. Moving parts that are the most common cause of breakdowns and defects in vacuum cleaners that are frequently turned on and off were also excluded. A compressed air vacuum cleaner is free from such limitations. Another important feature of technical vacuum cleaners is that they do not require electricity. This becomes more important in wet and hazardous environments.

When working with a pneumatic vacuum cleaner, it is not necessary to pull meters of wires to provide power. Compressed air for cleaning ensures much quieter operation than when using an electric vacuum cleaner. In addition, the workshop vacuum cleaner provides a very strong and direct flow of compressed air, i.e. high suction power of the vacuum cleaner, which results in extremely effective cleaning of any surface. These are professional vacuum cleaners that ensure work at the highest level.