When purchasing a compressor for a plant, we make sure that its performance is adapted to the current demand and production level. However, over time, this parameter may change as a result of the company's development, implementation of new solutions or opening new workstations. In such cases, it is necessary to increase the compressor's efficiency. Many entrepreneurs fear that it will be necessary to purchase a completely new device. However, this is not entirely true - in some cases it is possible to increase the efficiency of the compressor you already have. We advise you how to increase the efficiency of your compressor so that it can keep up with your company's growth.

What is the process of increasing compressor efficiency?

Improving compressor performance is possible through effective air compressor optimization. Optimization involves increasing the amount of compressed air produced in a given time unit and improving compressor parameters while reducing electricity consumption and thus reducing electricity bills.

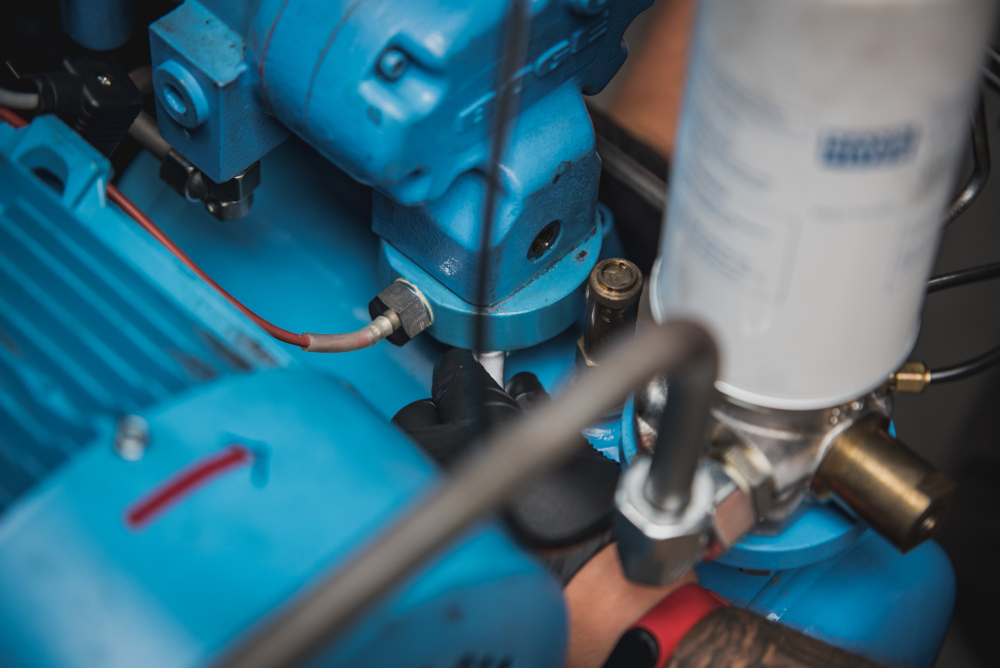

Before increasing the compressor's efficiency and implementing optimization of the operation of air compressors, it is necessary to determine the current needs in the production of this medium. In addition, the technical capabilities of both the compressor itself and the remaining components of the pneumatic system should be examined. It may also be useful to familiarize yourself with the structure of a screw compressor. Very often, an essential element of increasing the compressor's efficiency is changing and adapting the piping of pneumatic installations and improving the monitoring of detecting errors occurring in the compressed air system.

It happens that a company does not have the appropriate specialists in its human resources who will be able to determine the required quantity and quality of compressed air and then independently optimize the operation of the air compressor. Not every compressor user needs to know how to increase the compressor's efficiency. It is worth using the services of professional companies that specialize in servicing pneumatic installations. Companies of this type also conduct a compressed air audit and, if necessary, adjust the compressor parameters to the needs of the plant and its production, and increase the compressor's efficiency.

What can you do to increase the efficiency of your air compressor?

For DIY enthusiasts, it is also possible to carry out work on your own to increase the compressor's efficiency. The question then arises: how to increase the compressor's efficiency? You can achieve this effect in several ways. If the compressed air system is equipped with a separate air tank, it is possible to adjust the damper at the air outlet. This is the so-called suction regulator. Through the so-called By throttling the air damper, the flow of compressed air in the suction area is limited. This solution provides a large adjustment range, in the range of 60-100%, which is why it is one of the most frequently used methods of compressor regulation, optimization and increasing compressor efficiency.

Another option to optimize and improve compressor efficiency is to change the rotational speed of the drive motor. In practice, this results in stable pressure and smooth regulation of compressor performance. The method and scope of this process depends on the type and size of the air compressor. However, this optimization option is definitely best used on oil-injected compressors.

Optimizing the operation and increasing the efficiency of the compressor can also be achieved by appropriate arrangement of the pneumatic system components. Very often, individual elements of the compressed air system are arranged completely randomly. Only a compressed air audit reveals the problems caused by this small detail and how much it reduces the efficiency of the compressor and the operation of the entire compressed air system.

In addition, it is important to provide the devices with favorable conditions in order to optimize and increase the efficiency of the compressor. It is worth ensuring the appropriate temperature in the rooms and maintaining the appropriate humidity level. This will result in a higher quality of the working material, i.e. the air sucked into the compressor. This, in turn, will result in an increase in compressor efficiency. To meet these requirements, it is necessary to ensure adequate ventilation of the rooms and, in some cases, the use of professional air purifiers.