Spray painting used both in construction, e.g. for painting walls, and in painting, including in paint shops, requires the use of a paint gun connected to a compressor. The choice of compressor depends on several technical parameters and the degree of equipment utilization. Which painting compressor should you choose for garage use and which one for painting plants or construction sites?

Why is it worth using compressor painting?

Painting with a compressor has many advantages. It is undoubtedly cheaper than painting with a brush and at the same time provides much better results thanks to an even coating applied in multiple layers. Painting with a gun is also much faster, which helps increase work efficiency.

The paint compressor is designed to power the gun used for spray painting surfaces. It can be used both for painting car bodies and for painting walls, fence elements and others. Thanks to the use of a painting compressor, the varnish is sprayed both precisely and evenly, ensuring a smooth multi-layer surface.

Which painting compressor should you choose?

The choice of a compressor for painting should depend on both the technical parameters of the painting gun we have and the scope of work we intend to perform.

Compressor for semi-professional painting in painting and industrial plants

The choice of a painting compressor should depend on the scope of work that will be performed with the painting compressor. A different compressor will be needed for hobby work, another in a paint shop, and another in an industrial plant. The compressor's efficiency will play a key role here. Which painting compressor capacity will be best for each of the above applications?

The choice of a compressor for spray painting should depend on the technical requirements of the spray gun, and specifically on the nozzle diameter. If you plan to paint only small elements, e.g. for hobby or garage work, painting with a 50l compressor should be sufficient. Owners of painting workshops should consider purchasing a painting compressor with a capacity of at least 200l/min. However, it is worth remembering that the efficiency of the paint compressor cannot be lower than the efficiency of the gun. In the case of guns providing a larger painting surface, it may be necessary to use a compressor with a higher capacity - up to 500l/min. This applies especially to industrial plants where painting is implemented in the production line.

When choosing a compressor for spray painting, the technical parameters of the device will also be crucial. Among them, the capacity of the painting compressor will be important. The method of producing compressed air will also be important, which comes down to the question of whether to choose an oil or oil-free compressor and a piston compressor or a screw compressor.

Piston compressor or screw compressor - choose the best compressor

Both types of compressors can be used in the spray painting process. Both a piston compressor and a screw compressor can be used as a paint compressor for painting cars. Piston compressors, however, are not designed for continuous operation. As a result, when fulfilling many orders related to spray painting, it will not provide the appropriate amount of compressed gas, which will force downtime. Therefore, if you need a machine that will guarantee constant, efficient operation, you should consider purchasing a screw compressor.

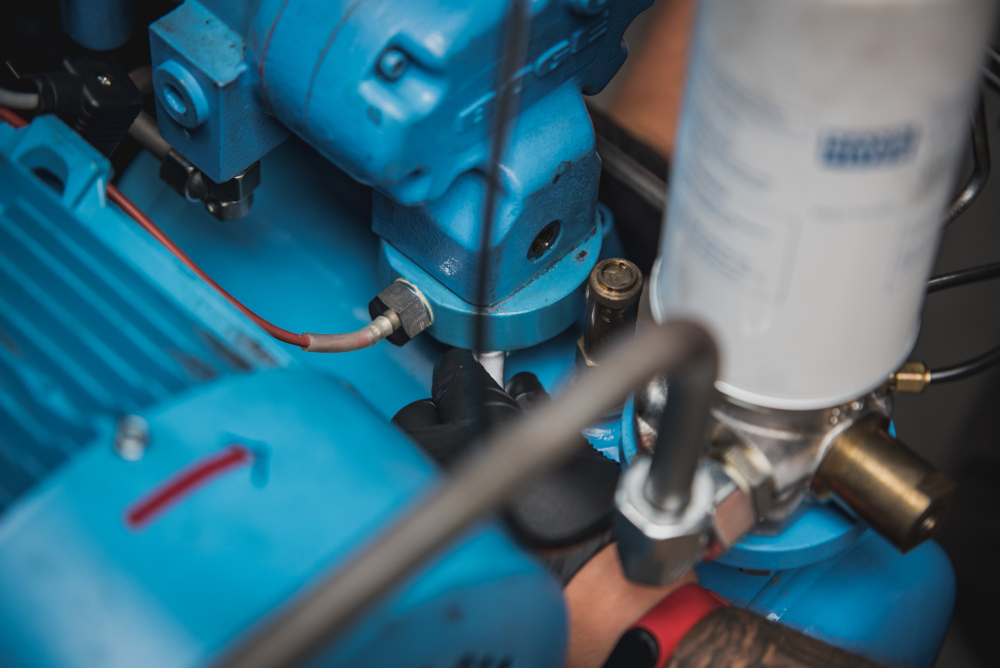

Screw compressors are perfect for powering guns for painting cars or large walls. High power, low energy consumption, low noise emission and high air purity class, thanks to the accessories used, guarantee fast, effective work and high quality of the paint coating.

Which compressor is best for painting - an oil or oil-free compressor?

In the case of painting or spray painting services, the purity class of compressed air is important. The quality of the compressed gauze produced by the painting compressor determines whether the paint coating will be uniform and durable. Which oil or oil-free compressor should I choose? In the case of an oil-free compressor, the risk of contamination of the compressed gas with oil particles is immediately reduced. Oil-free painting compressors, especially those of a professional or industrial nature, are more expensive and less durable than oil-based compressors. However, they are unrivaled when it comes to the purity of the compressed gas. In the case of oil painting compressors, the compressed air treatment system is crucial, as it will rid the gas of oil particles, water and other impurities. It must include air and oil filters, dryers (preferably adsorption or refrigeration), and cyclone separators. An indispensable element of the system will also be condensate drains, which will allow you to safely remove the water and oil condensate generated during treatment.