Cyclone separators and water-oil separators are commonly used as part of compressed air systems in industrial plants. What's the difference between these devices? What tasks are they designed to perform in compressed air systems?

What is a cyclone separator and what is it used for in compressed air systems?

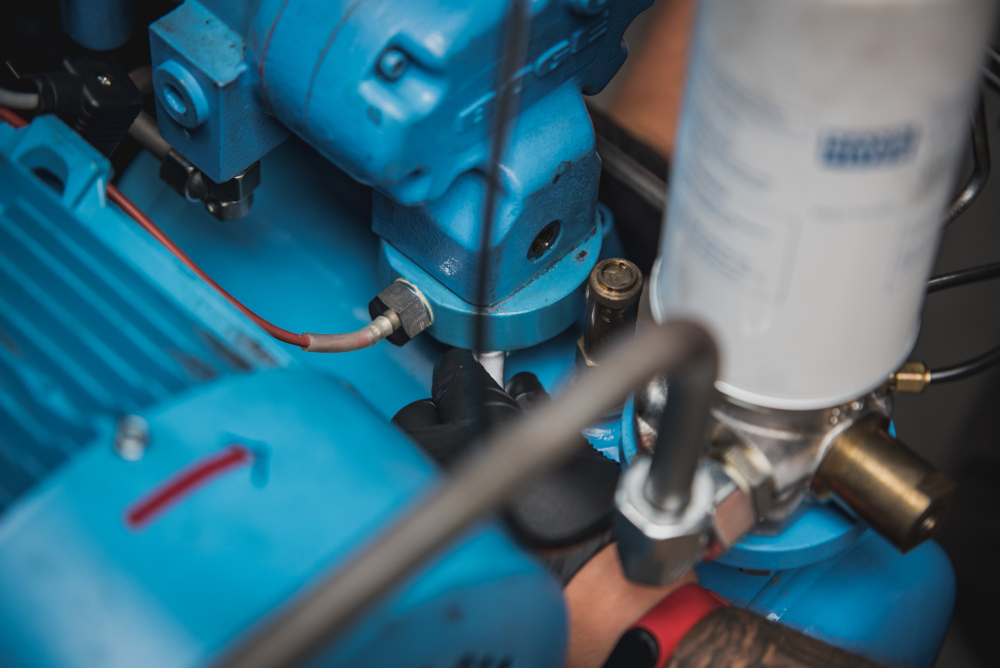

The cyclone separator is the basic element of the compressed air treatment system. It is responsible for eliminating a significant part of moisture from the compressed medium. The advantage of this device is its high efficiency, which translates into the elimination of up to 90% of moisture from the working medium. Moreover, the cyclone separator is a device with an extremely simple design. Moreover, it is low-failure.

How does a cyclone separator work? Its task is to introduce compressed air into swirling motion. In this way, under the influence of centrifugal force, moisture settles on the walls of the device and then flows to its bottom, where it is removed from the system using the condensate drain. It is worth emphasizing that along with water, other contaminants - e.g. oil particles and solid contaminants - precipitate from the compressed air. All this waste, together with water, forms condensate, which, if it comes from systems powered by an oil compressor, requires specialized disposal.

The advantage of the cyclone separator is low maintenance cost. The device has a relatively simple design that requires only little maintenance and operates reliably for a long time, which translates into lower operating costs. Importantly, the cyclone separator does not require external power or additional energy for its operation, which means no additional load on the compressed air system.

The cyclone separator is placed in the compressed air system before the dryer or other air treatment components to protect it from contaminants. You must know that without the use of a cyclone separator, there is no point in further drying the compressed air, for example using dryers. At the same time, the cyclone separator is easy to install and can be easily integrated into existing compressed air systems without the need for significant changes to the infrastructure.

Water-oil separator - what is it and what is it for?

It is worth emphasizing that high-performance systems operating at high temperatures and humidity can produce large amounts of condensate. If the air compression system operating in such conditions is based on an oil compressor, a very large amount of condensate may be formed during 8 hours of operation. It may be up to several hundred liters. This oil-containing substance must not be discharged into the sewage system. Remember that water-oil condensate is toxic to living organisms (both plants and animals) and its discharge into the environment is prohibited. Such activities are subject to high financial, administrative and criminal penalties.

The water-oil separator is used in compressed air systems to separate water and oil impurities from condensate. It is worth emphasizing that this substance consists of 99% water and 1% solid and oil impurities. At the same time, such a high oil content means that it cannot be directly discharged into the sewage system or the environment. Such condensate must be disposed of in a specialized manner, which is expensive. In addition, the accumulation of large amounts of condensate in the plant is also a problem. This is where the water-oil separator comes in handy. It allows most of the water to be separated from the condensate, significantly reducing its volume. This, in turn, contributes to reducing the costs associated with waste disposal and storage. The water separated from the condensate can be successfully discharged into the sewage system.