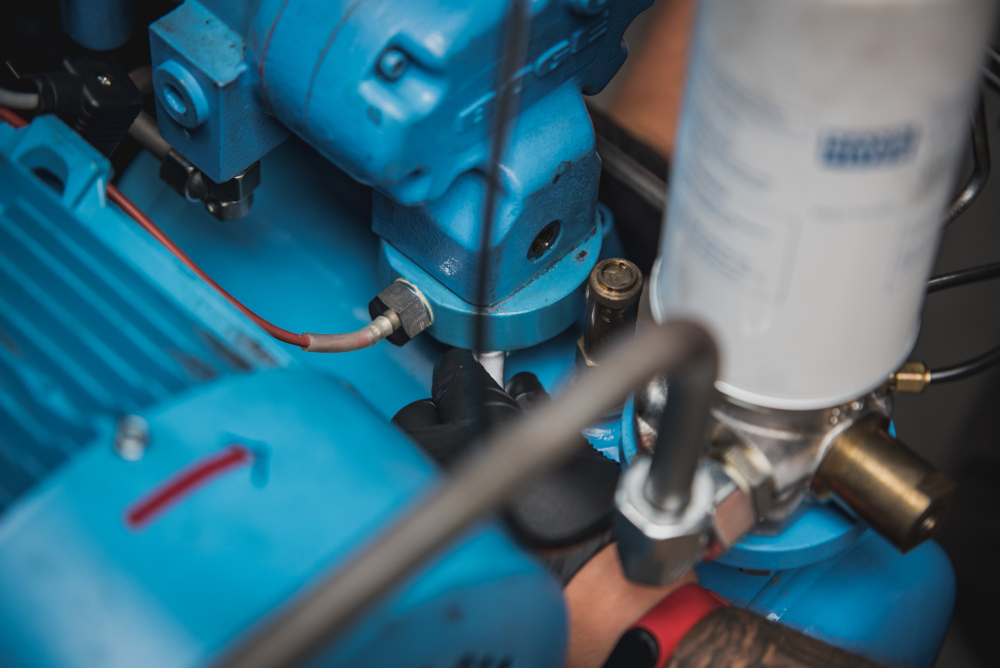

Pneumatic fittings are an indispensable element of creating a compressed air installation. They allow you to connect the source of the working medium - the compressor - with pipes supplying compressed air to the reception points. With the expansion of the installation, the number of compressors and the number of reception points, the degree of use of pneumatic connectors increases and requires the use of elements with different functions and structures. What pneumatic connectors are available on the market and what is their purpose?

Pneumatic fittings - types

The construction of a compressed air installation requires the use of a wide range of fasteners that will enable effective and tight distribution of the working medium. The process uses a large range of connectors for pneumatic lines and other components of compressed air systems, which influence the possibility of creating installations flexibly adapted to the requirements of production processes and technical conditions of facilities. Commonly used fasteners include AUTO connectors, also known as QUICK air connectors, quick connectors, twisted and circular pneumatic connectors, and a number of elements commonly used in the construction of installations. We encourage you to familiarize yourself with each type.

It is worth emphasizing that each pneumatic connector should be made of materials resistant to moisture, high pressure and temperature. Hence, instead of steel, the dominant material in pneumatic connectors is pure and electroplated brass. When used in places with increased sanitary requirements or difficult (aggressive conditions), stainless steel is used.

QUICK type pneumatic plug-in connectors

A popular type of connector is the "quick" type plug-in connector. They allow for quick, simple and tight installation, while ensuring the required tightness, which is achieved automatically after inserting/screwing the cable. Quick type pneumatic hose connectors can operate in a wide range of temperatures and operating pressure up to 12 bar. It is worth using solutions that are equipped with a special sealing coating.

"Quick" pneumatic plug connectors are available in a wide range of models, so you can easily select elements tailored to the needs of a specific pneumatic installation. The assortment includes straight connectors, straight connectors with a shut-off valve, elbows, angle connectors, grommets also with a non-return or shut-off valve, as well as various tees, four-pieces, splitters and plugs. This type of pneumatic connectors are available with both male and female threads, which allows for repeated connection and disconnection without the risk of losing properties and tightness.

Quick connectors

The quick connector is the most popular pneumatic connector used to connect components within compressed air systems. They enable quick connection of tools and devices with power cables and ensure high tightness while installing quickly. This type of pneumatic connectors is used both in industry and in services (e.g. dental units) and professional work. Quick connectors work well in networks with operating pressures from 0 to 35 bar and operating temperatures from -20 to +100 degrees C.

Screwed pneumatic connectors

Another type of connectors for pneumatic lines are twisted connectors. This type of connectors is characterized by the fact that it does not use any sealing. This function is performed by the nut, which seals the connection by pressing. Screwed pneumatic connectors are used in places where there is a risk of temperatures higher than +70 degrees Celsius, stresses or twisting of cables. Screwed connectors are used in installations where the operating pressure ranges from -0,95 to 15 bar.

Pneumatic ball joints

Ball joints are a stable, damage-resistant and reliable connection used in installations using various media: compressed air, water, oils and others. It is recommended to use this type of joints wherever high flow is expected.

Other elements of pneumatic systems

In installations for the distribution of pressurized media, other elements are also used that influence the smoothness of transmission. These include, among others: ball valves, manifolds, manifolds and distributors, thread sealing elements, screw clamps, as well as noise silencers and pneumatic hose fittings.

Take advantage of our experience in building compressed air installations

Correct design and implementation of a pneumatic installation requires knowledge and experience of our team of engineers and technicians. The design of the compressed air distribution system must be tailored to the individual needs and requirements of the planned production processes. At the same time, building a tight and functional distribution system will ensure adequate power supply to pneumatic devices. The use of appropriate pneumatic connectors, professionalization of the tasks performed and a sense of responsibility guarantee a system that meets the needs of your plant. Contact our company - at CZEMAR we are open to the needs of our clients also in the field of consultations and professional advice.