Purifying and drying compressed air is a key element in improving its quality. Compressed air coolers play an important role in this process. They are responsible for reducing the air temperature and lowering the moisture content. Below we explain when a compressed air cooler is useful in a plant, what is its principle of operation and possible applications.

Do I need a compressed air cooler?

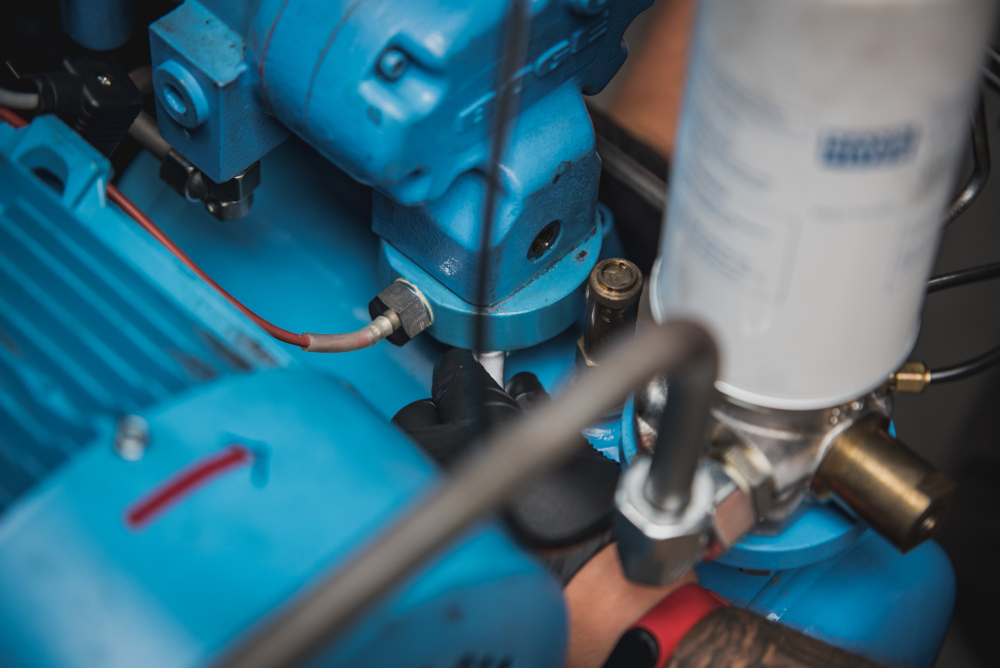

The high quality of compressed air produced by a factory compressor is of great or even crucial importance in many companies. Compressed air characterized by high levels of humidity and high temperatures does not meet the requirements of high quality. Therefore, it is necessary to effectively cool the air and remove moisture from it. A compressed air cooler is perfect for this purpose. The air cooler, by installing it behind the compressor or buffer tank, guarantees the highest efficiency and protection of all compressed air treatment devices. The design of this type of cooler provides effective protection for both refrigerating and adsorption dryers as well as compressed air filters. Therefore, regardless of what the compressed air installation diagram looks like in a given plant, purchasing an air cooler for the compressor will be a good solution.

Principle of operation of compressed air coolers

The construction of the cooler is not overly complicated. The basic elements of a compressor cooler are a heat exchanger and an axial fan. The heat exchanger is made of copper pipes reinforced with aluminum cooling fins. In turn, a high-efficiency axial fan forces air from the environment and directs it directly through the heat exchanger, thus achieving the desired cooling effect. The air cooler for the compressor reduces the temperature of the compressed air to approximately 10°C above the ambient temperature. Therefore, at the same time, the air cooler serves as an end fan for hot air.

Application of compressed air coolers

The potential use of a compressor cooler depends on the type of cooler selected. One of them is the intercooler, which serves as a charge air cooler. It is most often used in internal combustion engines. Its role is to reduce the temperature of the compressed air before it is delivered to the engine. This results in higher engine efficiency and power.

The term intercooler is used to refer to an air cooler used in turbo engines. The best examples are aircraft engines or gas turbine compressors. An intercooler is a device placed between the compressor stages, which is where its name comes from. The air cooler located behind the compressor is called an aftercooler.

The intercooler comes in two variants. A standard intercooler has both the inlet and outlet of cooled air on the same side. The cross-flow intercooler version is equipped with an inlet and outlet located on opposite sides. Therefore, the cross-flow intercooler provides a slightly better cooling effect. Air coolers of this type are also used in gas turbine installations. This action is intended to reduce the temperature of the partially compressed air.

Moreover, the refrigeration compressor can also be successfully used in difficult conditions, not only in halls and plants where there are good conditions for the devices to work. The compressor air cooler can also be used in engines that run and are started with compressed air. However, cooperation with a professional company in the assembly and implementation of an air cooler for the compressor ensures the best efficiency and precise adaptation to the customer's requirements and the specificity of the industry in which it works.